CNC Mills High Performance Hurco VMX Series

CNC is a machine that makes parts by cutting materials and cutting them into desired shapes. CNC is mainly used in the manufacturing and construction industries. Even individuals can use CNC. However, there are very few CNCs available for home use, and it is quite expensive, so most people will not do it.

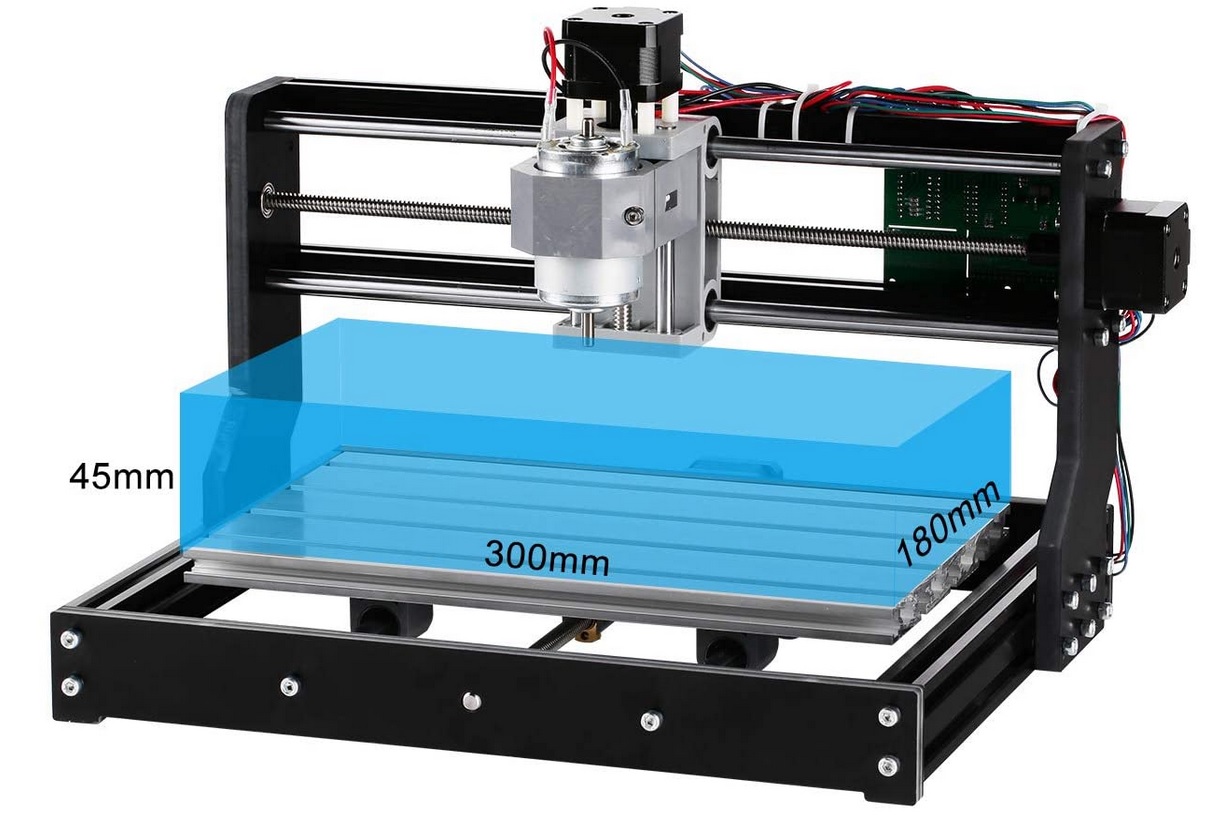

CNC Freesmachine Lasergraveerder 3018 PRO

CNC machining is one of two ways that engineers, machinists, or makers can generate a physical part from a computer design file, with the other being 3D printing, known as additive manufacturing. Image Source: Concerning Reality. The contrast between these two techniques is stark. CNC machining, like other machining processes is a subtractive.

New 5 Axis CNC Router Machine HY3040 from ChinaCNCzone Price Less than 3000USD

CNC is een afkorting voor Computer Numerical Control en is een benaming voor computergestuurde machines die worden gebruikt om materialen en halffabricaten te bewerken. Men treft CNC gestuurde machines aan in verschillende metaalproductiebedrijven maar ook in andere productiebedrijven worden ze gebruikt zoals in de glasverwerking, kunststofverwerking en houtbewerking.

CNC Machine Service and Repair About CNC Machines Common Problems and Failures

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like SolidWorks or MasterCAM. The software writes G-code that the controller on the.

Wat is een CNC draaier / CNC verspanen?

CNC is instrumental in fabricating engine components, transmission parts, chassis, and intricate body panels with precision and consistency. Machines also create prototypes and components, allowing engineers to test designs before mass production. Automated CNC systems use machining in the mass production of automotive parts.

Hurco CNC Machine Technology at EASTEC 2019

The four basic CNC machining processes mentioned require specific equipment to perform these operations, which are what we refer to as CNC machines. Indeed, the term "CNC machines" is quite broad since there are many types of CNC machines: there are approximately 20 major categories and over 40 subcategories of commonly used machine tools.

The Best CNC Machines For Your Business

Step 1: First, the CNC machining process starts with a CAD model, a 3D model designed on a CAD software for the desired shape and size to be created. You may either want to design the part yourself if you have the skills, or have a designer create the model. Step 2: The CAD model is then imported into a CAM software which prepares the model for.

What are CNC Machines? Jaibros

In CNC machining, the computer numerical controls are responsible for moving the parts of the machine to complete the prescribed process. While some manual inputs can be made by an operator depending on the tooling involved, the computer will operate the machinery according to its program. Utilizing computer numerically controlled machine tools.

CNC Machine 600x900mm

Toegepaste varianten zijn o.a. : CNC-zetten, CNC-frezen en CNC-lasersnijden. Wat is een CNC machine hout? Met behulp van een CNC machine (computer numerical control machine) is het mogelijk om verschillende materialen te bewerken. Dit is ideaal voor productiebedrijven waarbij de materialen op grote schaal dezelfde bewerkingen nodig hebben.

5axis CNC Machine in 2022 Best Tips & Tricks

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers. With CNC machining, three-dimensional cutting tasks can be.

5 Common Types of CNC Machines 2023 FotoLog

CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it. Metal is the most commonly used material in CNC machining, and the end result is a.

What is CNC machining How does it improve the manufacturing efficiency IBE Electronics

The CNC machine has developed significantly in size and complexity since its beginnings in the 1950s by adapting to digital technologies. The Beginnings of the CNC Machine. Before the advent of CNC machines, the ability of operators to fabricate parts was limited, resulting in poor adjustments or losses, and worker productivity remained low.

5 Surprising Applications of CNC Machines iStoryTime

CNC machines: CNC machines are computer-controlled machines that can perform various tasks, such as cutting, drilling, engraving, and 3D printing.They use different tools and methods depending on the material and the desired shape. CNC milling machines: CNC milling machines are used to make metal parts with high precision and accuracy.They have a movable bed and a spindle that moves up and down.

CNC Turning Advanced Precision Machining

CNC overview. A "CNC Pantograph" is a machine controlled by a computer (or by a control board in the professional versions) on which an electro-spindle is mounted, on which a cutting tool is mounted (drills, cutters ). Typically a CNC pantograph is characterized by 3 axes of movement, that is the X, Y and Z axes.

G Code CNC Basic Programming Mastering CNC Machines

Evolving from the numerical control (NC) machining process which utilized punched tape cards, CNC machining is a manufacturing process which utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock material—e.g., metal, plastic, wood, foam, composite, etc.—into custom parts and designs.

VMC1890L large heavy cutting 5 axis cnc machine Linear Guideway sino cnc machining center

CNC Machines. CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1. These computerized machines, called CNC machines, are capable of operating with high precision and.